Functional Safety Operations and Maintenance

Operations and maintenance lifecycle phases are crucial in ensuring the integrity and reliability of the Safety Instrumented System (SIS). Safety instrumented functions (SIFs) may no longer function correctly without a commitment to operations and maintenance, harming people, assets, business continuity, reputation, and the environment. Therefore, it is essential to manage risk reduction measures and inspect and maintain the SIS throughout the safety lifecycle.

NeoDyne’s operations and maintenance services include:

- Proof Testing

- Functional Safety Management System

- Managed Services Plan

Proof Testing

Proof testing is an integral part of the maintenance of a SIS and is used to detect dangerous hidden failures in safety systems. As process safety systems typically operate in low-demand mode, where the safety instrumented function (SIF) remains dormant over time, proof testing uncovers undetected failures. Properly designed proof tests ensure the integrity of the SIS over the mission time.

Proof test procedures can vary in complexity and can be divided into full functional (end-to-end) or partial tests. A partial proof test only tests a percentage of a device’s failure modes, whereas a full proof test verifies the correct operation of all sensing element(s) and actuating devices. Proof testing can be completed online or offline during a shutdown or turnaround. Online testing requires careful planning and coordination and is very much dependent on the nature of the process, the process materials and associated risk.

Writing and implementing a proof test procedure is an important step to ensure the integrity of the SIF over its lifetime. The test procedures should provide sufficient details to ensure they can be safely and consistently performed at required intervals.

Functional Safety Management System

NeoDyne can work with you to help establish a Functional Safety Management System (FSMS) based on your existing ISO 9001:2015 quality management system (QMS). The ISO 9001:2015 standard is based on key quality management principles, including the process approach and continuous improvement.

We foster continuous improvement through a variety of processes, including internal and external auditing, corrective and preventive action and training.

We perform a gap analysis to identify any FSMS gaps and make recommendations on how to achieve a fully compliant FSMS, as required by IEC 61511 and 61508.

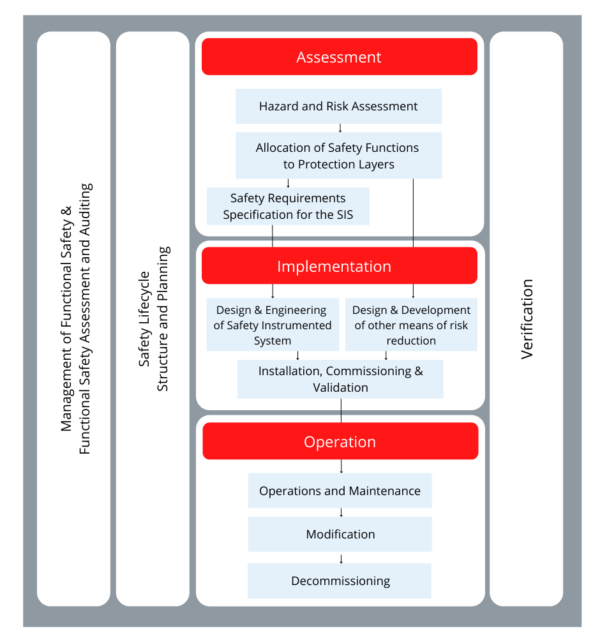

IEC 61511 Process Lifecycle

Managed Services Plan

We are passionate about customer service and adopt a “customer first” approach in all our interactions. We provide scheduled and unscheduled technical support and 24/7/365 systems support. We can tailor a support package to suit our customers’ individual needs and guarantee minimum response times.

Scheduled Support Service

The NeoDyne scheduled support service has been designed to preserve and enhance SIS reliability by identifying and actioning issues before they become problematic. Our services include:

- A review of the functional safety management plan, FSMS and QMS

- Lifecycle stage functional safety assessments

- SIS performance reviews

- Proof testing

- Compliance assessments against safety standards and EU regulations

Unscheduled Support Service

We also provide an out-of-hours callout service through our Support Pager System. This unscheduled callout service includes:

- First-line response telephone support

- Unscheduled callout available 24/7/365

- Guaranteed response times for functional safety engineer to site

We have an expansive knowledge of our products and their on-site implementation, ensuring we offer a knowledgeable and responsive service for all our installed Safety Systems.

Driving technology for leading brands

Integration & Digital Manufacturing Customers

We supply the Life Science, Food & Beverage, Data Centre and Energy industries.

Our key markets are for robust applications requiring innovation, reliability, longevity and specialised know-how.