Machine Safety

Dangers for people, machines and the environment exist throughout the entire machine lifecycle. From risk assessment to risk validation, our comprehensive machine safety services help our customers reduce risk, improve compliance, and optimise production. This includes working with industrial machinery vendors/suppliers to ensure compliance with EU Directives and safety standards to validating that our customer’s safety systems are correctly installed and functioning.

We partner with global technology companies, including HIMA, Siemens and Rockwell, to provide our customers with leading-edge safety solutions and services. We use multiple tools across all stages of the machine safety lifecycle, including EXIDA exSILentia, DGUV Sistema and others. We provide both turnkey safety system solutions and bespoke solutions specific to a customer’s individual requirements.

Risk Assessement

Risk assessment is the first step in the machine safety lifecycle to identify hazards and compliance with safety standards and regulations. We conduct our risk assessments according to ISO 12100, a Type-A standard that specifies the terminology, principles, and methodology to achieve safety in machinery design. ISO 12100’s principles are based on the design, use, incidents and accidents associated with machinery. Therefore, implementing the standard’s procedures with appropriate industry knowledge and expertise helps identify hazards and assess their risks.

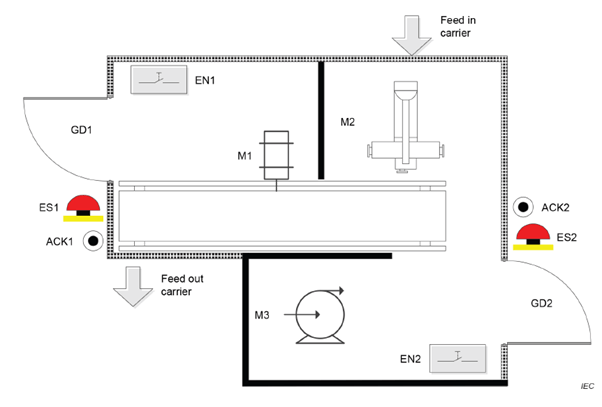

We develop a proposed safety concept following our machinery risk assessment, detailing:

- Inherent safe design measures where practicable

- Safeguarding in the form of fixed and moveable guarding solutions

- Safeguarding in the form of safety control measures, including appropriately selected electrical, electronic, pneumatic and/or hydraulic control systems and machine actuators

- Interlocks with Guardlock, trapped keys, light curtains and scanners

- Complementary safeguards such as E-stops

- De-energisation and shutdown trips

- Safety configuration specification and verification

- Safety Logic design and analysis

- Human Factors Analysis

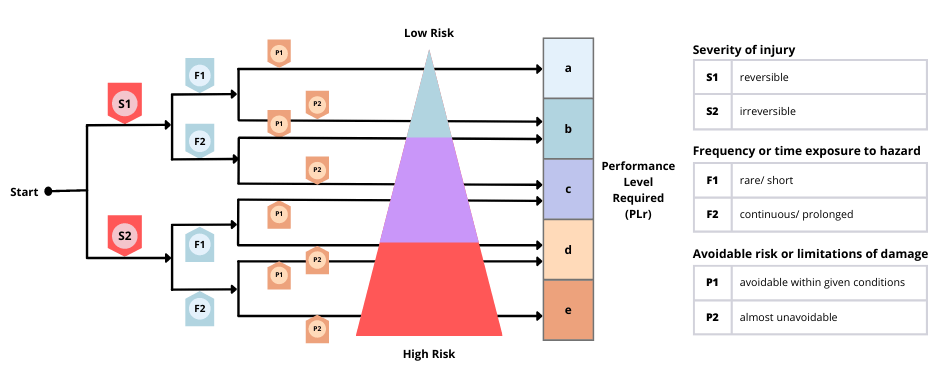

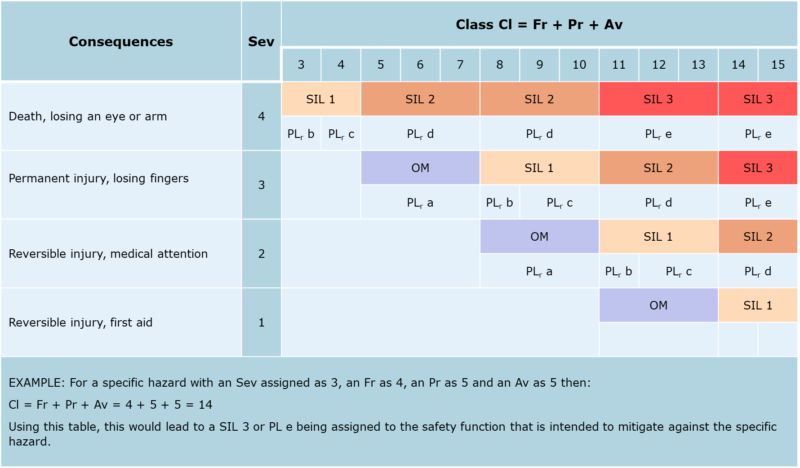

- SIL or Performance levels for machine safety

- Conformity assessment against EU Norms harmonised to the Machinery Directive

Risk Verification / Validation

Functional Safety is a branch of reliability engineering, and we believe in robust risk verification processes that rely on qualified personnel performing systematic and documented analysis. Our TÜV Nord, TÜV Rheinland and EXIDA certified engineers verify and validate machine SIL and performance levels using Type-B standards, including IEC 62061 and ISO 13849-1. Type-B standards cover safety requirements common to the design of most machines, covering general safety aspects and special protective devices.

ISO 13849 is the safety standard for machinery control systems and provides the framework for designing and integrating safety-related parts, including software. The standard calculates and assesses a control system’s performance levels (PL), i.e. safety-related parts’ ability to perform a safety function under hazardous conditions.

IEC 62061 is an alternative standard with the same purpose and outcome as ISO 13849 but with a different methodology. This standard provides for a methodology that more closely follows the IEC 61508 framework and approach.

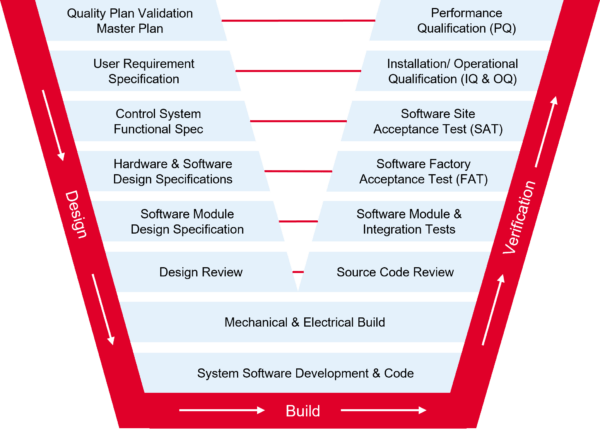

Risk Validation involves an inspection and assessment of safety-related parts to ensure they meet their defined PL or SIL levels as per IEC 62061 and ISO 13849-1. All safety-related software and hardware is verified and validated using the V-model and involves functional testing. NeoDyne produces a test report detailing design discrepancies where found and best practice recommendations to ensure the continued safe operation of industrial machines and plants.

Safety Software

We partner with global technology companies, including HIMA, Siemens and Rockwell, to provide our customers with leading-edge safety software solutions.

The safety standards, IEC 62061 and ISO 13849, prescribe variants of the V-model to develop and test safety applications in a PLC depending on the complexity and type of programming language involved. The V-model focuses on verification and validation activities, linking each development phase to an associated test phase. By adhering to the V-model, we provide our customers with a high degree of transparency and clearly defined and comprehensive software development processes.

Cybersecurity

Most safety functions involve safety logic and black channel networks as part of the logic solver element. The safety standards require access control but do not specify in detail how this should be achieved. Under the current environment, all networked deployments must be treated as having a cybersecurity dimension.

NeoDyne’s cyber security team can help your organisation implement and maintain an operational technology (OT) cyber security program to ensure the security and continuity of your systems in line with the NIS directive and based on international standards, including IEC TS 63074:2021. As IEC-62443 IC33 Cyber Security Assessment Specialists and IEC-62443 IC34 Cyber Security Design Specialists, we can deliver a complete solution for NIS directive compliance and provide services for the full cyber security lifecycle.

Click here to find out more about our Network and Cybersecurity assessment services.

CE Marking Services

Under the Machinery Directive 2006/42/EC regulations, all plant machinery and parts must meet essential health and safety requirements to be placed on the market or put into service, protecting workers and consumers alike.

We conduct conformity assessments to ensure compliance with EC Directives (Machinery Directive and ATEX Directive 94/9/EC) and relevant safety standards. Furthermore, we produce a risk assessment and safety design (where appropriate) for any design flaws or omissions. We also assume the role of an authorised representative to carry out CE marking and help our customers compile all necessary documentation under EU regulations.

Driving technology for leading brands

Integration & Digital Manufacturing Customers

We supply the Life Science, Food & Beverage, Data Centre and Energy industries.

Our key markets are for robust applications requiring innovation, reliability, longevity and specialised know-how.