CPG and Packaging MES

“Needs Driven” MES Solutions

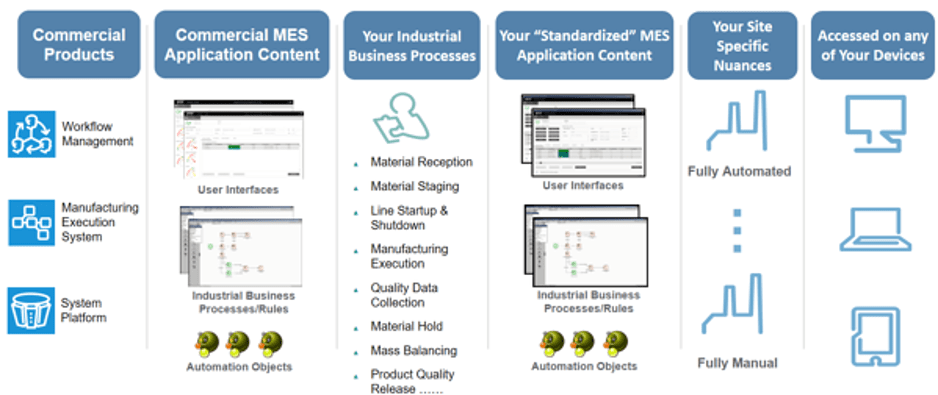

NeoDyne offers “Needs Driven” MES Solutions that combine Commercial Off-The-Shelf (COTS) platforms with Use Case Specific configurations to maximise flexibility and meet customer requirements.

Through a detailed requirements analysis phase with Business Managers, Operations Managers, Plant Operators, IT and OT Teams – NeoDyne identifies where a MES Solution can offer value to that particular business.

We also determine what pre-existing technologies and platforms can be leveraged to achieve MES goals, providing an appropriate platform or platform set to meet the remaining needs.

Integration with ERP, SCADA and other systems

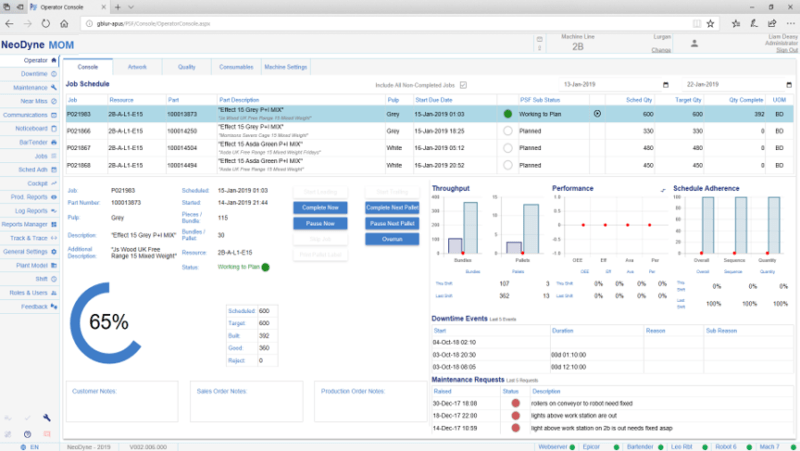

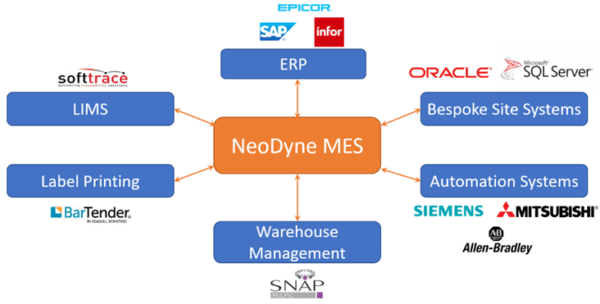

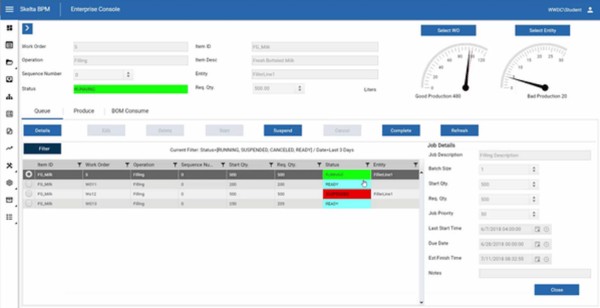

MES / MOM solutions form a critical layer in any manufacturing business by linking Business Planning data from ERP, for example, with the Execution and Control processes on the Plant Floor.

NeoDyne MES solutions offer many and varied mechanisms for integration with ERP, SCADA, and other on-site customer systems, enabling improved coordination of operations, consolidation of data, and better visibility, while also maintaining fast and reliable transfer of information.

We have considerable experience with building NeoDyne MES/MOM solutions across many platforms.

Eliminate Paper as an Information Carrier on the Shop Floor

Maximise Efficiency and Minimise Training

Working with process owners and end-users, NeoDyne examines existing paper-based processes and work-flows, to consolidate where possible, and replicate where appropriate, these systems in an electronic infrastructure.

Deep Data, NOT Big Data

Within our MES solutions, data is stored in a highly organised database schema, with use case driven reports, and data visualisation and extraction tools which enable Deep Data analysis.

Drive System Use and Compliance Through Visibility

Our solutions allow for Closed Loop communication of data, whereby manually recorded information is acknowledged and actioned transparently on MES.

Being Future Ready

NeoDyne understands that businesses are continually evolving with ever-changing MES system requirements. We develop our MES solutions in a modular fashion to allow for easy inclusion of new features and for the system to scale as the site or enterprise grows.

The modules support broad manufacturing management functionality ranging from performance optimisation to inventory, production and quality operations management.

This modular and scalable approach reduces the cost and time-to-value of a MES system. Solutions can start with a standalone module and scale to an integrated MES as return-on-investment is realised.

Our MES/MOM Process

Assess Needs & Goals

- Adopt a “Needs driven” approach

- Run comprehensive strategy workshops

- Identify distinct business needs and operator needs

- Identify where MES/MOM can add value to the business

Select Platform(s)

- Identify existing infrastructure that can be leveraged

- Derive the right platform combination to meet end-user requirements. Every Business is different

- Balance regulatory compliance with solution configurability

Agile Execution

- Adopt a cyclical design, development and review process

- Adapt to requirement changes

- Perform rapid continuous reviews to identify and address challenges early and effectively

- Deliver open source solutions with continuous design and development input from end-users, IT and OT teams

Driving technology for leading brands

Integration & Digital Manufacturing Customers

We supply the Life Science, Food & Beverage, Data Centre and Energy industries.

Our key markets are for robust applications requiring innovation, reliability, longevity and specialised know-how.

Connect with a NeoDyne Engineer

Do you have a project

to discuss?

Are you facing an engineering challenge that requires expert guidance? Or a vision that needs to be brought to life? Meet our innovators, and together, we’ll shape tomorrow.